About Plastic Engineering Calculator

Plastic Engineering Calculator

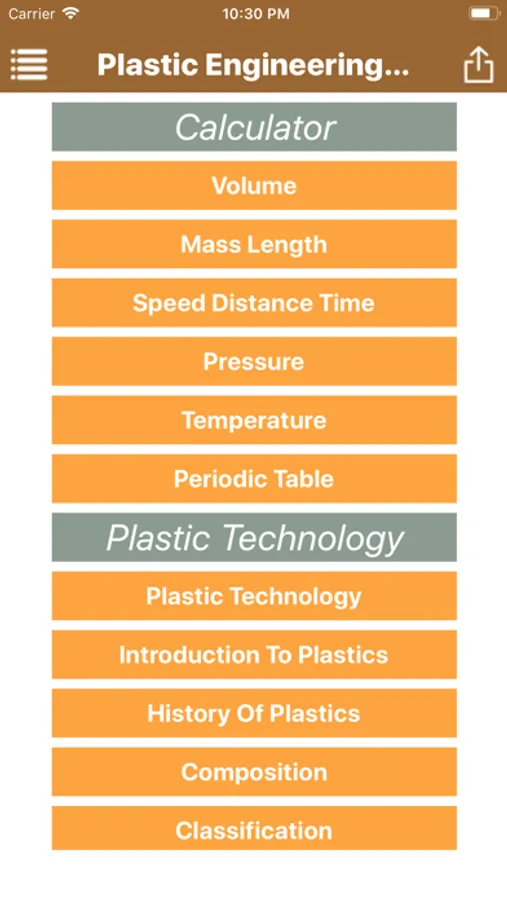

This App Covers:

Volume Calculator

Mass Length Calculator

Speed-Distance-Time Calculator

Pressure Calculator

Periodic Table Calculator

Temperature Calculator

Plastics engineering encompasses the processing, design, development, and manufacture of plastics products. A plastic is a polymeric material that is in a semi-liquid state, having the property of plasticity and exhibiting flow. Plastics engineering encompasses plastics material and plastic machinery. Plastic Machinery is the general term for all types of machinery and devices used in the plastics processing industry.The nature of plastic materials poses unique challenges to an engineer. Mechanical properties of plastics are often difficult to quantify, and the plastics engineer has to design a product that meets certain specifications while keeping costs to a minimum. Other properties that the plastics engineer has to address include: outdoor weatherability, thermal properties such as upper use temperature, electrical properties, barrier properties, and resistance to chemical attack.

In plastics engineering, as in most engineering disciplines, the economics of a product plays an important role. The cost of plastic materials ranges from the cheapest commodity plastics used in mass-produced consumer products to the very expensive, specialty plastics. The cost of a plastic product is measured in different ways, and the absolute cost of a plastic material is difficult to ascertain. Cost is often measured in price per pound of material, or price per unit volume of material. In many cases however, it is important for a product to meet certain specifications, and cost could then be measured in price per unit of a property. Price with respect to processibility is often important, as some materials need to be processed at very high temperatures, increasing the amount of cooling time a part needs. In a large production run cooling time is very expensive.

Plastics Engineering

Plastics engineers use their knowledge of chemistry, physics, engineering and math to develop everyday products. Read on to discover education and career options in this field.

Inside Plastics Engineering

Materials engineers may choose to specialize in plastics. The field of plastics engineering involves the application of scientific and engineering principles to the development of a wide variety of polymer products. From airplane wings to golf clubs and a host of goods in between, a plastics engineer solves material-related problems with the goal of designing and developing products with improved performance and durability. Plastics engineers may find careers in government, academia and the manufacturing industry. Typical job titles may include materials research engineer, production planner, process engineer or plastic product designer.

There are a variety of opportunities in materials engineering and closely related fields, such as chemical engineering. Study.com has pertinent information about some of the different degree, career and online education options in this field.

Education Information

A plastics engineer requires a broad array of knowledge. Thus, students in a plastics engineering program study subjects such as chemistry, physics and mathematics. Degrees in materials science and engineering may be found from the associate's to the doctoral level. Most engineers require at least a bachelor's degree. Graduate degrees may be required for some research positions. Due to rapidly advancing technology, continuing education is necessary for engineers to stay competitive. Review the articles listed below to delve deeper into some of these educational programs' requirements.

This App Covers:

Volume Calculator

Mass Length Calculator

Speed-Distance-Time Calculator

Pressure Calculator

Periodic Table Calculator

Temperature Calculator

Plastics engineering encompasses the processing, design, development, and manufacture of plastics products. A plastic is a polymeric material that is in a semi-liquid state, having the property of plasticity and exhibiting flow. Plastics engineering encompasses plastics material and plastic machinery. Plastic Machinery is the general term for all types of machinery and devices used in the plastics processing industry.The nature of plastic materials poses unique challenges to an engineer. Mechanical properties of plastics are often difficult to quantify, and the plastics engineer has to design a product that meets certain specifications while keeping costs to a minimum. Other properties that the plastics engineer has to address include: outdoor weatherability, thermal properties such as upper use temperature, electrical properties, barrier properties, and resistance to chemical attack.

In plastics engineering, as in most engineering disciplines, the economics of a product plays an important role. The cost of plastic materials ranges from the cheapest commodity plastics used in mass-produced consumer products to the very expensive, specialty plastics. The cost of a plastic product is measured in different ways, and the absolute cost of a plastic material is difficult to ascertain. Cost is often measured in price per pound of material, or price per unit volume of material. In many cases however, it is important for a product to meet certain specifications, and cost could then be measured in price per unit of a property. Price with respect to processibility is often important, as some materials need to be processed at very high temperatures, increasing the amount of cooling time a part needs. In a large production run cooling time is very expensive.

Plastics Engineering

Plastics engineers use their knowledge of chemistry, physics, engineering and math to develop everyday products. Read on to discover education and career options in this field.

Inside Plastics Engineering

Materials engineers may choose to specialize in plastics. The field of plastics engineering involves the application of scientific and engineering principles to the development of a wide variety of polymer products. From airplane wings to golf clubs and a host of goods in between, a plastics engineer solves material-related problems with the goal of designing and developing products with improved performance and durability. Plastics engineers may find careers in government, academia and the manufacturing industry. Typical job titles may include materials research engineer, production planner, process engineer or plastic product designer.

There are a variety of opportunities in materials engineering and closely related fields, such as chemical engineering. Study.com has pertinent information about some of the different degree, career and online education options in this field.

Education Information

A plastics engineer requires a broad array of knowledge. Thus, students in a plastics engineering program study subjects such as chemistry, physics and mathematics. Degrees in materials science and engineering may be found from the associate's to the doctoral level. Most engineers require at least a bachelor's degree. Graduate degrees may be required for some research positions. Due to rapidly advancing technology, continuing education is necessary for engineers to stay competitive. Review the articles listed below to delve deeper into some of these educational programs' requirements.