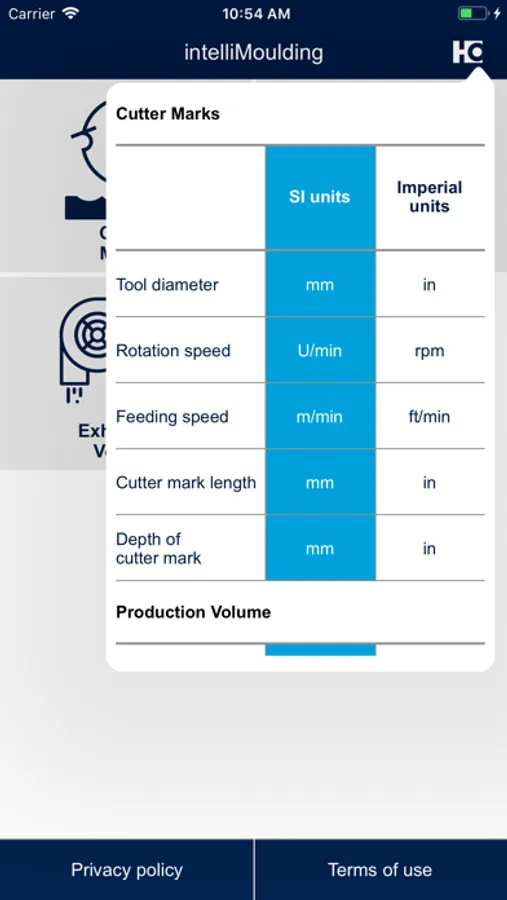

About intelliMoulding

The intelliMoulding App supports the operation of a planing and profiling machine. The app provides various digital tools that are precisely tailored to the requirements of a planing and profiling system. The aim is to minimise errors, make production more efficient and to utilise optimization potential. The intelliMoulding App is suitable for employees in small workshops or in industrial companies.

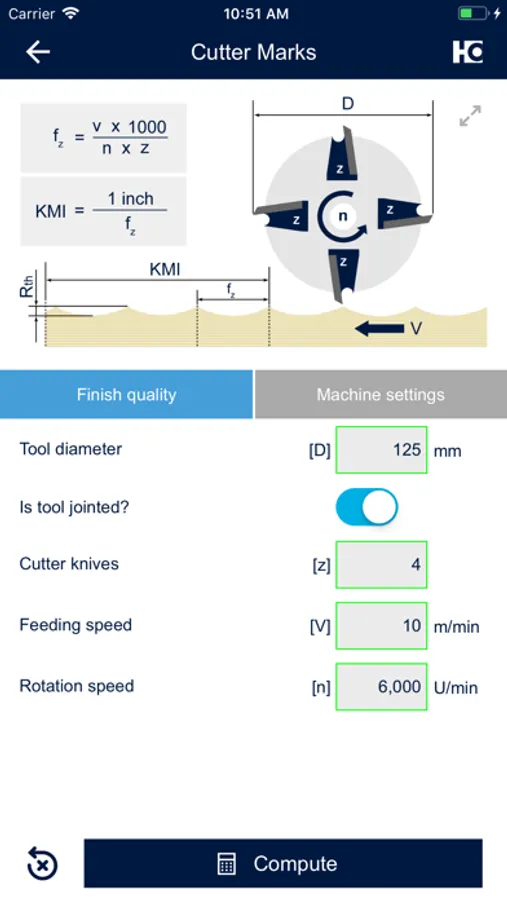

Cutter mark:

- When wood surfaces are machined with a rotating tool, the so-called cutter mark (or knife mark, planing step) occurs.

- The wood turn appears as a wave pattern on the wood surface. The stroke width, the distance between two planing combs, is influenced by the number of knives in the tool, the feed rate and the spindle speed.

- The surface quality of the planed workpiece is influenced, among other things, by the planing impact.

- With the intelliMoulding App, the cutter mark width can be determined from the specified machine parameters. At the same time, however, it is also possible to specify a desired cutter mark width and calculate the machine parameters required to achieve this quality level.

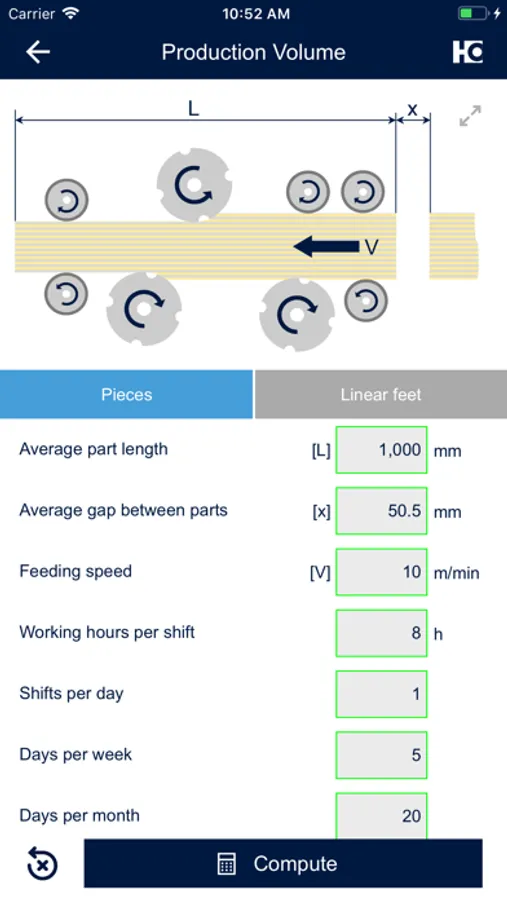

Production volume:

- With this function, the expected production quantity on a planing and profiling machine can be determined quickly and easily.

- On the basis of entered data on workpiece dimensions, feed rate and working time, the app roughly calculates the number of workpieces produced per day, per week and per month.

- The calculation result can be displayed either in pieces or in running meters.

- The tool provides quick answers if the production is to be estimated and planned roughly.

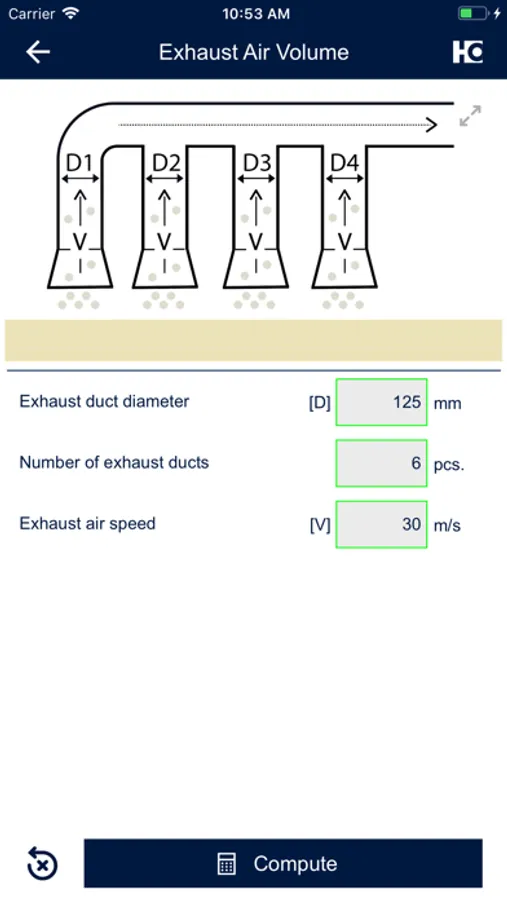

Exhaust Air Volume:

- Easily and conveniently determine the extraction volume of a planing and profiling machine.

- The app calculates the required volume of an extraction system from the number of extraction sockets, their diameter and the extraction speed.

- The result is calculated as volume per minute, per hour or per shift.

- The tool can be used, for example, to quickly determine whether an existing extraction system has sufficient capacity for connecting a new planing and profiling machine.

Cutter mark:

- When wood surfaces are machined with a rotating tool, the so-called cutter mark (or knife mark, planing step) occurs.

- The wood turn appears as a wave pattern on the wood surface. The stroke width, the distance between two planing combs, is influenced by the number of knives in the tool, the feed rate and the spindle speed.

- The surface quality of the planed workpiece is influenced, among other things, by the planing impact.

- With the intelliMoulding App, the cutter mark width can be determined from the specified machine parameters. At the same time, however, it is also possible to specify a desired cutter mark width and calculate the machine parameters required to achieve this quality level.

Production volume:

- With this function, the expected production quantity on a planing and profiling machine can be determined quickly and easily.

- On the basis of entered data on workpiece dimensions, feed rate and working time, the app roughly calculates the number of workpieces produced per day, per week and per month.

- The calculation result can be displayed either in pieces or in running meters.

- The tool provides quick answers if the production is to be estimated and planned roughly.

Exhaust Air Volume:

- Easily and conveniently determine the extraction volume of a planing and profiling machine.

- The app calculates the required volume of an extraction system from the number of extraction sockets, their diameter and the extraction speed.

- The result is calculated as volume per minute, per hour or per shift.

- The tool can be used, for example, to quickly determine whether an existing extraction system has sufficient capacity for connecting a new planing and profiling machine.