About HeronTrack

Anytime, anywhere have a look where is your equipment/tools.

HeronTrack is a solution for the management of small equipment and equipment used by construction workers or technical services. We have developed a tag (smart sensor) to be installed on or in the tool, such as a ladder, a compressor, a grinding wheel, etc. The tag communicates via Bluetooth (BLE) with a smartphone.

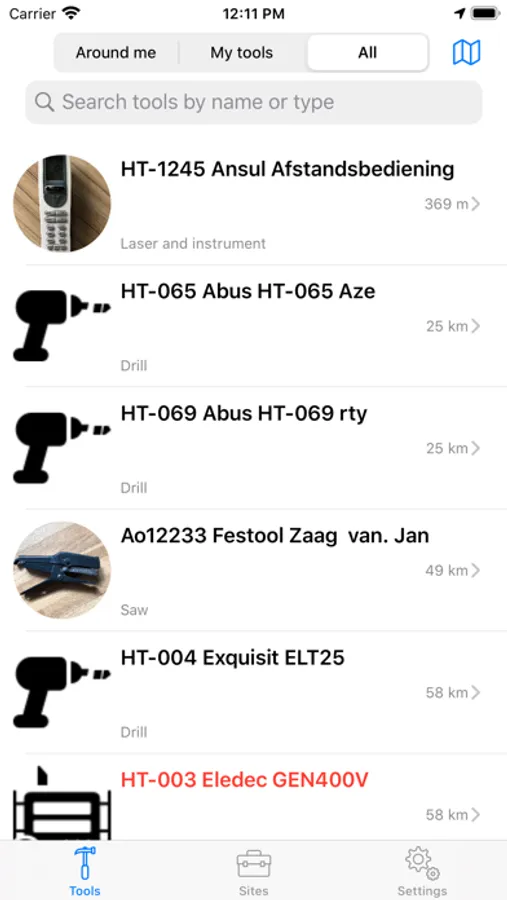

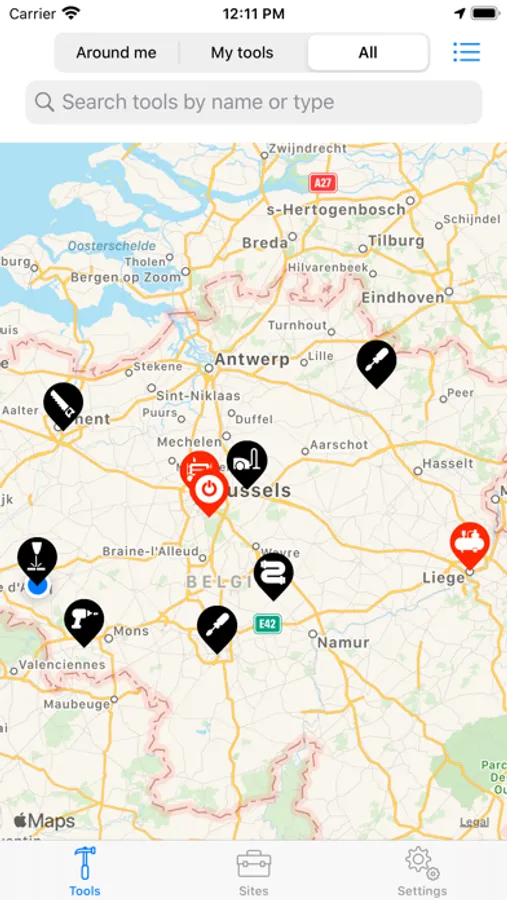

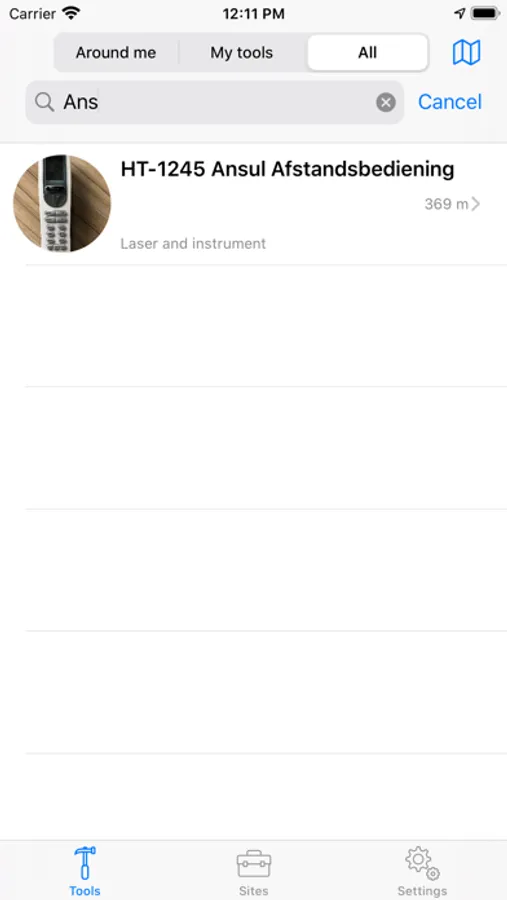

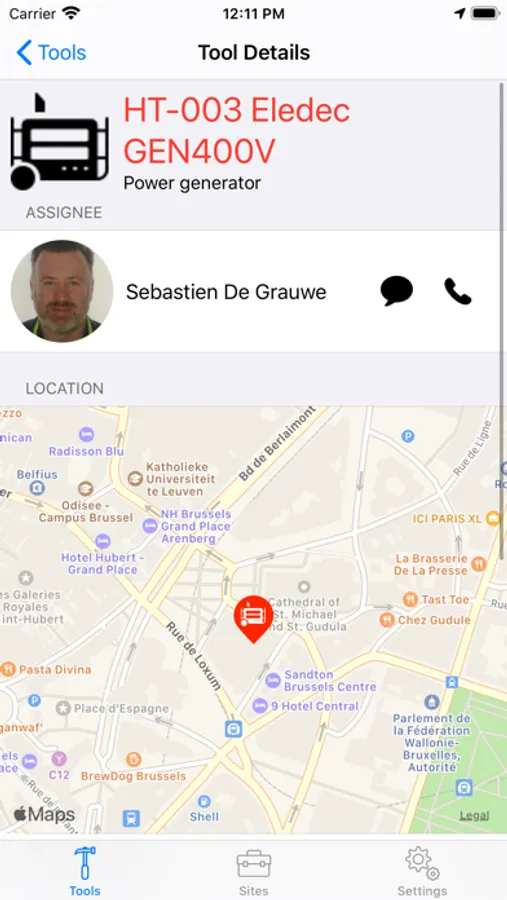

The mobile application allows the field worker to detect the tools around him/her and to link the GPS position of the smartphone to the tool, so that this information together with the ID number of the tag (UID) can be sent to our platform. This way, the information is available in the form of reports or visual information on the tagged tool's map.

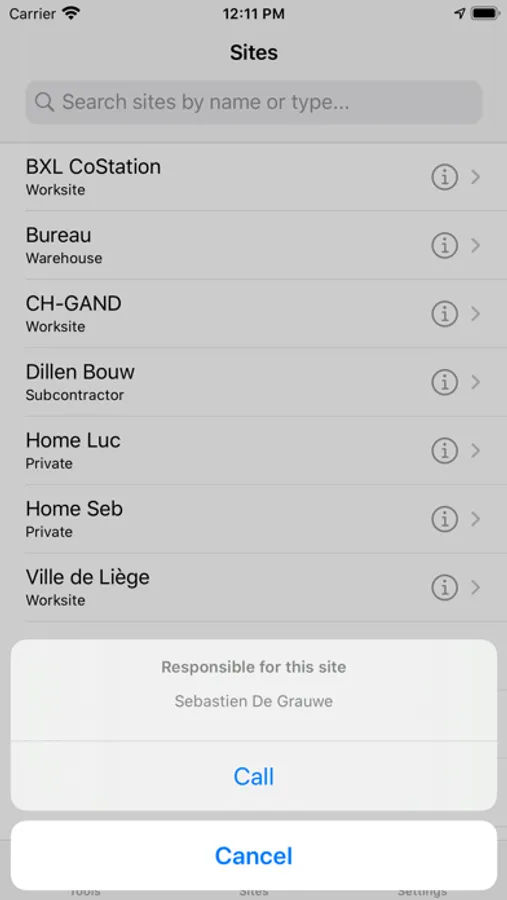

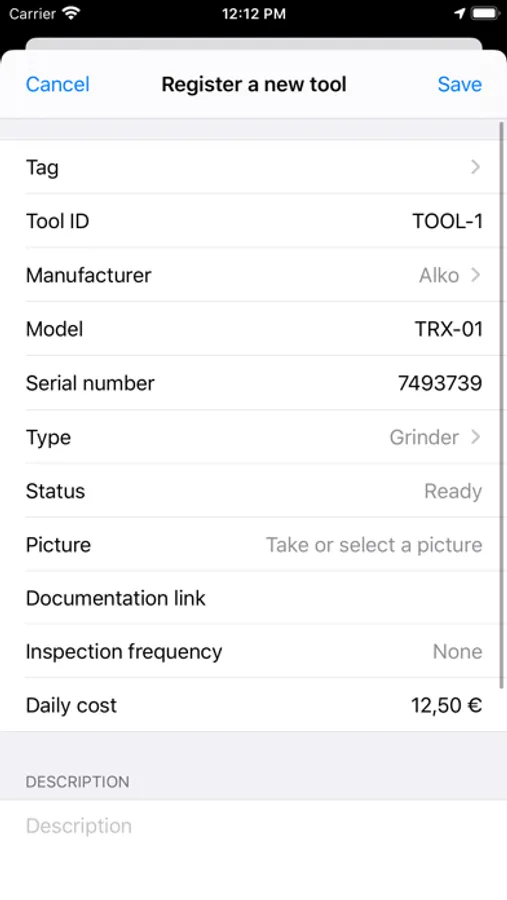

Via the web- and mobile solution it is possible to trace the tools, it is also possible to manage the inventory autonomously (without human intervention) and offers a solution for the inspection of the equipment and the registration in the digital logbook, to show the good condition of the tools. Users always have insights into the availability of the tool, but also the location, the state, the user, the daily costs ...

HeronTrack brings a solution for

- Inventory management: it is very difficult nowadays for construction companies to make inventories because the vehicles have to be permanently on site due to productivity, deadlines and efficiency. As a result, the inventory is usually carried out once a year during the construction holidays. It is during this check that broken tools are found that were never reported or that purchases were made of tools that were not needed. It is necessary to have an overview of equipment and tools at all times in order to make the right decisions.

- Management of inspections: it is mandatory to be able to show that the equipment used is in good condition for accident prevention and insurance. There are regulations for preventive and periodic checks, depending on the type of equipment. This management is also difficult because the personnel responsible for managing the tools or the technician who needs to go to the inspection lose a lot of time to locate them. Without having a real-time overview of where the tool to be inspected is located, it is very cumbersome to schedule an inspection and a lot of time is lost to find the tool in question. After the inspection, the information must be kept in case of a check to prove that the rules have been applied.

Cost control: as explained in the item "inventory", a good inventory can be used to check the purchase of tools that are not necessary. Moreover, it is always necessary to allocate the costs of using the tool to a site and therefore a daily entry of the cost of small equipment can be registered.

Today, many companies in the construction sector have IT solutions for vehicle management, man and machine hours, projects, invoicing, but they still work with paper booklets for managing small equipment and planning maintenance and inspections. There is a need for digitization of this management and therefore an IT tool for tracing small equipment!

HeronTrack is a solution for the management of small equipment and equipment used by construction workers or technical services. We have developed a tag (smart sensor) to be installed on or in the tool, such as a ladder, a compressor, a grinding wheel, etc. The tag communicates via Bluetooth (BLE) with a smartphone.

The mobile application allows the field worker to detect the tools around him/her and to link the GPS position of the smartphone to the tool, so that this information together with the ID number of the tag (UID) can be sent to our platform. This way, the information is available in the form of reports or visual information on the tagged tool's map.

Via the web- and mobile solution it is possible to trace the tools, it is also possible to manage the inventory autonomously (without human intervention) and offers a solution for the inspection of the equipment and the registration in the digital logbook, to show the good condition of the tools. Users always have insights into the availability of the tool, but also the location, the state, the user, the daily costs ...

HeronTrack brings a solution for

- Inventory management: it is very difficult nowadays for construction companies to make inventories because the vehicles have to be permanently on site due to productivity, deadlines and efficiency. As a result, the inventory is usually carried out once a year during the construction holidays. It is during this check that broken tools are found that were never reported or that purchases were made of tools that were not needed. It is necessary to have an overview of equipment and tools at all times in order to make the right decisions.

- Management of inspections: it is mandatory to be able to show that the equipment used is in good condition for accident prevention and insurance. There are regulations for preventive and periodic checks, depending on the type of equipment. This management is also difficult because the personnel responsible for managing the tools or the technician who needs to go to the inspection lose a lot of time to locate them. Without having a real-time overview of where the tool to be inspected is located, it is very cumbersome to schedule an inspection and a lot of time is lost to find the tool in question. After the inspection, the information must be kept in case of a check to prove that the rules have been applied.

Cost control: as explained in the item "inventory", a good inventory can be used to check the purchase of tools that are not necessary. Moreover, it is always necessary to allocate the costs of using the tool to a site and therefore a daily entry of the cost of small equipment can be registered.

Today, many companies in the construction sector have IT solutions for vehicle management, man and machine hours, projects, invoicing, but they still work with paper booklets for managing small equipment and planning maintenance and inspections. There is a need for digitization of this management and therefore an IT tool for tracing small equipment!