About Deming Funnel

This app shows how productivity may be increased and variation reduced with a thorough understanding of variation. Deming Funnel (or Nelson Funnel) experiments are implemented in Interactive 3D Augmented Reality.

The Deming Funnel experiment is a lesson in understanding variation. It shows that if we do not have a full understanding of variation, our best efforts can make things worse. It is essential to understand how to use and interpret Process Behavior Charts (control charts). It is essential to be able to identify and differentiate between assignable causes (special causes) and common causes.

APP USAGE

You must be STANDING. The virtual funnel is about a meter high. You can start exploring immediately, or tap the icon at the top right, tap “START” and read the instructions.

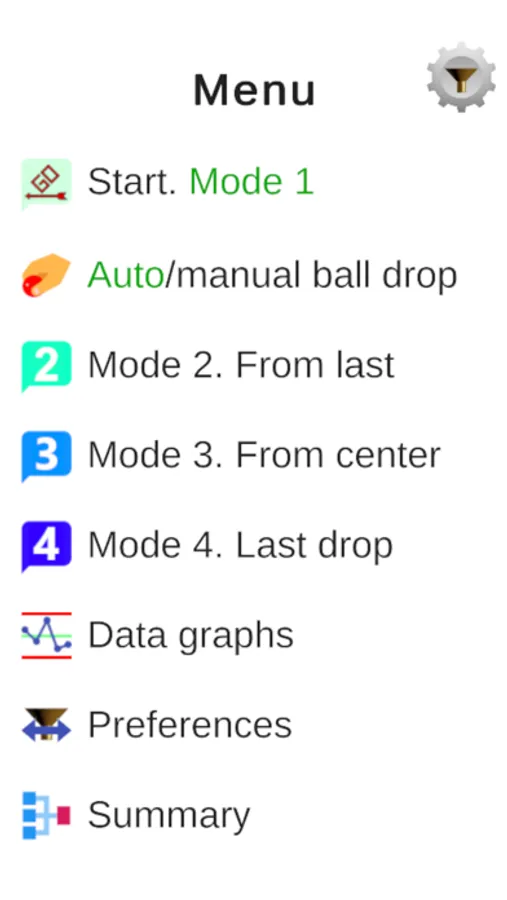

The app allows both manual interaction with the virtual objects, as well as automatic operation.

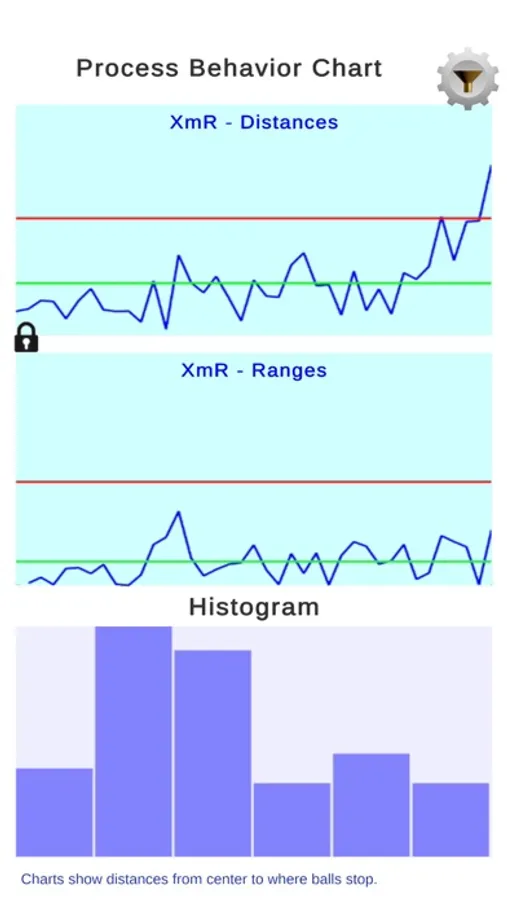

Each of the 4 modes are presented, together with many real life examples of each mode. Patterns of the results for each mode appear. Control charts and histograms are generated for each. Many of the common misunderstandings and misuse of control charts are demonstrated.

Camera access is required for the virtual objects. There is no collection of personal data.

TAMPERING

The experiments demonstrate the deleterious effects of various forms of tampering.

Perhaps the most well known example of tampering is Mr Bill Smith. Bill tampered with his molding procedure, which led to a wildly out-of-control process. It happened to drift "as much as 1.5 sigma", which led to the Six Sigma Scam. If Mr Smith had a better understanding of variation, Six Sigma might never have been born. Mr Smith’s efforts were an example of Mode 2 tampering.

Professor Deming rescued Ford Motor Co from disaster in 1982. They promptly turned their backs on him and bought into the Six Sigma Scam. A study over hundreds of Six Sigma projects showed an average of 220,000 defects per million AFTER improvement for "successful" projects! Any company wanting success has no excuse to turn from the giants of Quality: Dr Shewhart; Professor Deming; Dr Wheeler. The Deming Funnel is one of the first steps to QUALITY and PRODUCTIVITY.

WHY AUGMENTED REALITY

The Deming Funnel experiment is very powerful but difficult to implement in the real world. Professor Deming himself rarely demonstrated it. The table needs to be perfectly flat and marking the paper and moving the funnel accurately, is slow, clumsy and difficult. Interactive Augmented Reality overcomes these difficulties ... and makes the experiments far more engaging.

The app can be used by individuals, or screen cast for lectures. Knowledge of Process Behavior Charts (control charts) is recommended.

The Deming Funnel experiment is a lesson in understanding variation. It shows that if we do not have a full understanding of variation, our best efforts can make things worse. It is essential to understand how to use and interpret Process Behavior Charts (control charts). It is essential to be able to identify and differentiate between assignable causes (special causes) and common causes.

APP USAGE

You must be STANDING. The virtual funnel is about a meter high. You can start exploring immediately, or tap the icon at the top right, tap “START” and read the instructions.

The app allows both manual interaction with the virtual objects, as well as automatic operation.

Each of the 4 modes are presented, together with many real life examples of each mode. Patterns of the results for each mode appear. Control charts and histograms are generated for each. Many of the common misunderstandings and misuse of control charts are demonstrated.

Camera access is required for the virtual objects. There is no collection of personal data.

TAMPERING

The experiments demonstrate the deleterious effects of various forms of tampering.

Perhaps the most well known example of tampering is Mr Bill Smith. Bill tampered with his molding procedure, which led to a wildly out-of-control process. It happened to drift "as much as 1.5 sigma", which led to the Six Sigma Scam. If Mr Smith had a better understanding of variation, Six Sigma might never have been born. Mr Smith’s efforts were an example of Mode 2 tampering.

Professor Deming rescued Ford Motor Co from disaster in 1982. They promptly turned their backs on him and bought into the Six Sigma Scam. A study over hundreds of Six Sigma projects showed an average of 220,000 defects per million AFTER improvement for "successful" projects! Any company wanting success has no excuse to turn from the giants of Quality: Dr Shewhart; Professor Deming; Dr Wheeler. The Deming Funnel is one of the first steps to QUALITY and PRODUCTIVITY.

WHY AUGMENTED REALITY

The Deming Funnel experiment is very powerful but difficult to implement in the real world. Professor Deming himself rarely demonstrated it. The table needs to be perfectly flat and marking the paper and moving the funnel accurately, is slow, clumsy and difficult. Interactive Augmented Reality overcomes these difficulties ... and makes the experiments far more engaging.

The app can be used by individuals, or screen cast for lectures. Knowledge of Process Behavior Charts (control charts) is recommended.