About Unconfined Test

The Unconfined Compression Test Application was designed to be used in conjunction with a GCTS Wireless Point Load Testing System equipped with Unconfined Compression Test Platens. This application allows the user to easily perform and record data for an unconfined compression test by connecting wirelessly with the GCTS Point Load Testing System through Bluetooth.

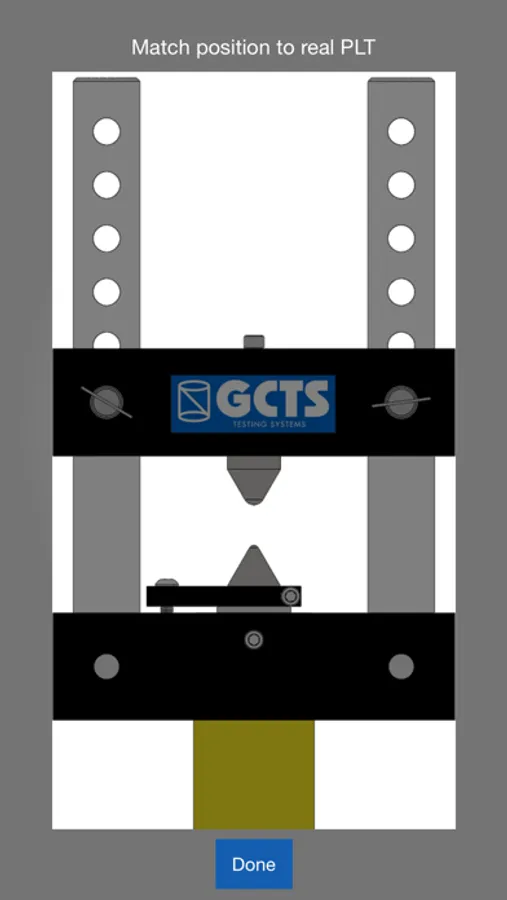

All steps of test preparation can be easily read and transmitted to the application for ease-of-use. The operator can place a calibrated specimen in the Point Load Testing System for calibration of the crosshead position. The application uses a two-point calibration for the crosshead position.

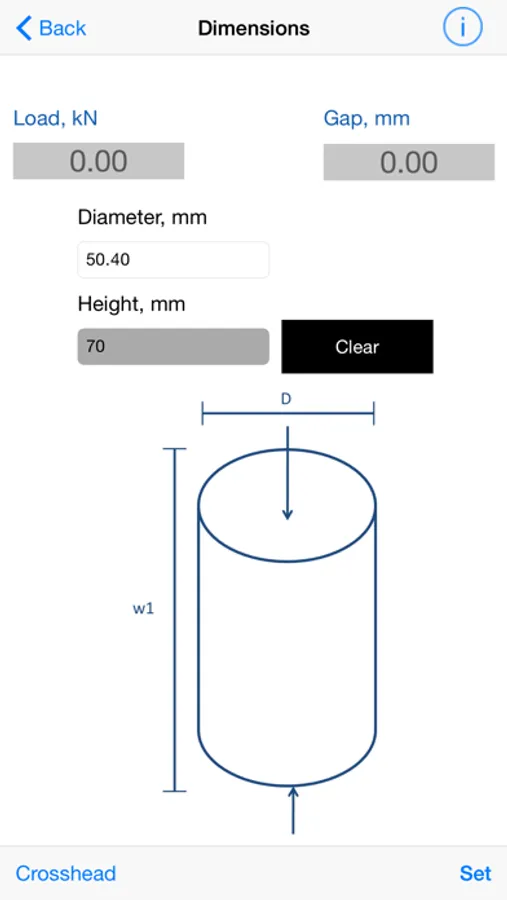

By simply placing the specimen in the apparatus and applying a small load, the height of the specimen can be automatically measured. The user can continue to apply a load to the specimen, as the application will automatically begin the test once the height has been measured at the threshold load.

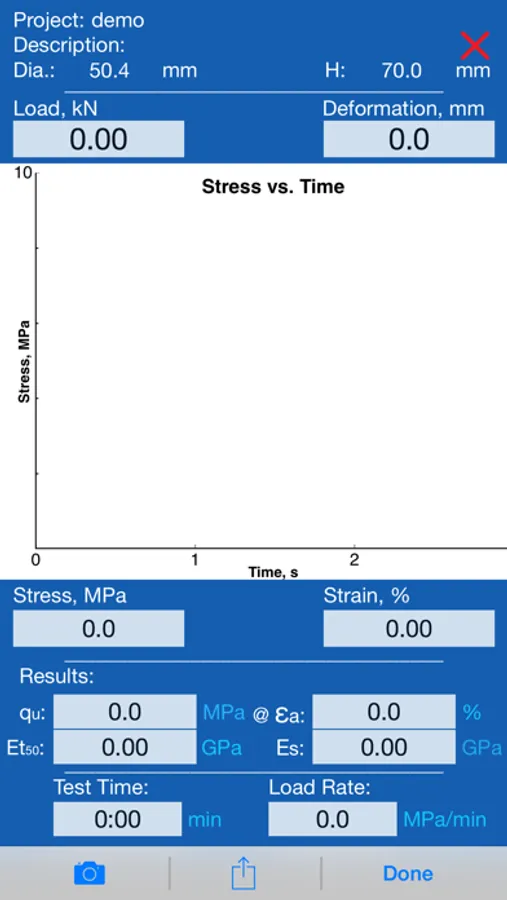

The application automatically records the load and the height of the specimen during the test and creates a graph of the data in real-time. The unconfined compressive strength of the specimen will be automatically calculated and displayed at the end of the test. The application calculates and records the stress and strain on the specimen during testing, and a graph of this data can also be viewed in real-time. It also automatically calculates the Tangent Modulus at 50% strength. A real time display of the loading rate helps the user apply loads at the appropriate rate.

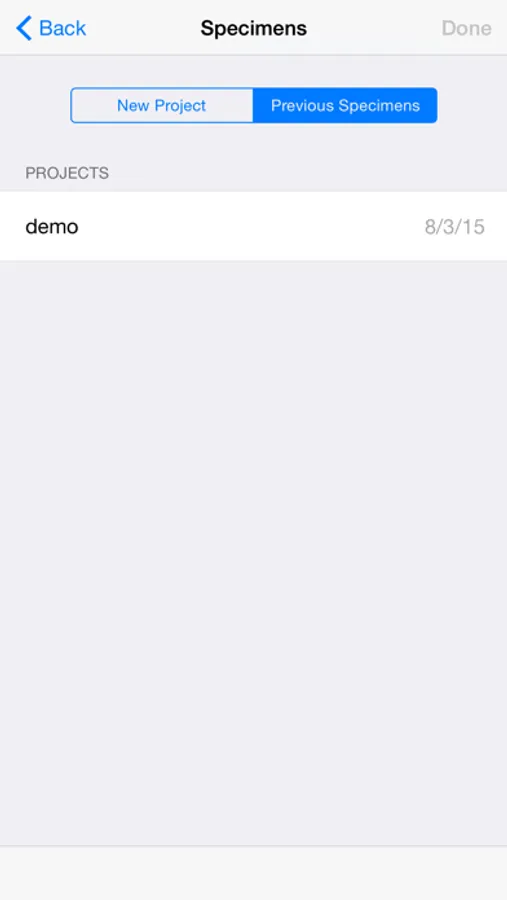

After performing the test, the data can be emailed direction from the application as a CSV spreadsheet. Test results are also saved in the application for later viewing.

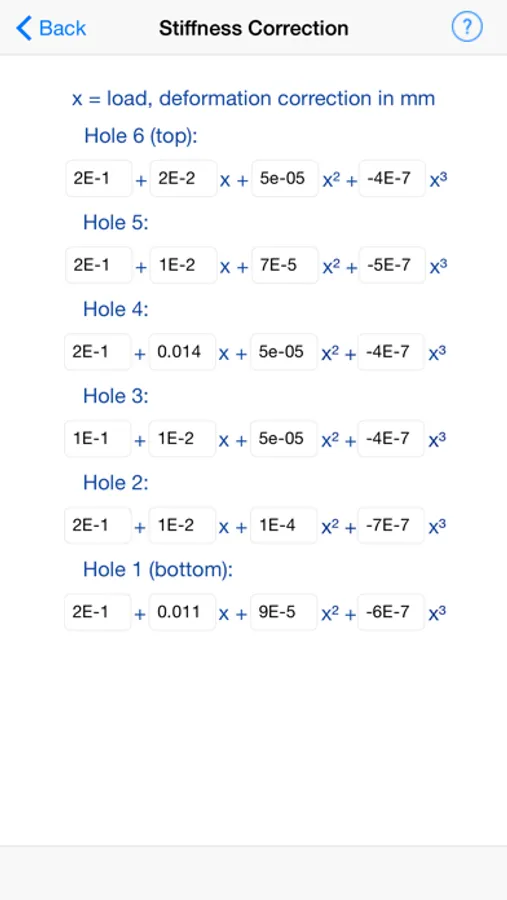

This application also makes automatic corrections to the data to account for the frame deformation compliance. This correction gives the frame a “Virtual Infinite Stiffness” and all results are presented with this correction already performed. This means that the results given are extremely accurate.

This application must connect once to a GCTS Wireless Point Load Testing System before it can be used. Once it has connected to a system, the application may be opened and data may be viewed from any location.

All steps of test preparation can be easily read and transmitted to the application for ease-of-use. The operator can place a calibrated specimen in the Point Load Testing System for calibration of the crosshead position. The application uses a two-point calibration for the crosshead position.

By simply placing the specimen in the apparatus and applying a small load, the height of the specimen can be automatically measured. The user can continue to apply a load to the specimen, as the application will automatically begin the test once the height has been measured at the threshold load.

The application automatically records the load and the height of the specimen during the test and creates a graph of the data in real-time. The unconfined compressive strength of the specimen will be automatically calculated and displayed at the end of the test. The application calculates and records the stress and strain on the specimen during testing, and a graph of this data can also be viewed in real-time. It also automatically calculates the Tangent Modulus at 50% strength. A real time display of the loading rate helps the user apply loads at the appropriate rate.

After performing the test, the data can be emailed direction from the application as a CSV spreadsheet. Test results are also saved in the application for later viewing.

This application also makes automatic corrections to the data to account for the frame deformation compliance. This correction gives the frame a “Virtual Infinite Stiffness” and all results are presented with this correction already performed. This means that the results given are extremely accurate.

This application must connect once to a GCTS Wireless Point Load Testing System before it can be used. Once it has connected to a system, the application may be opened and data may be viewed from any location.