About Pitram Connect

Designed by Micromine specialists, Pitram Connect offers mine sites seamless third party data integration through Pitram Restful Integration Services (PRIS), and will be available on your mobile device.

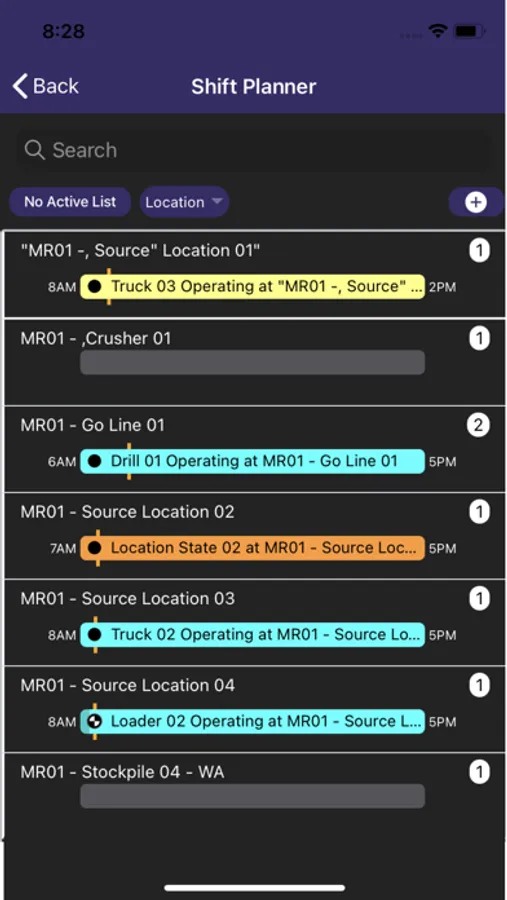

Pitram Connect provides insight into your mine site at your fingertips. The mobile application will allow users to retrieve information about their assets (people, equipment, production, locations, time allocations) without directly impacting mine control personnel or having to be at a workstation. For example, a production supervisor would like to know the mines current production delivery to the production plant, quickly determine the status of a location, know the amount of time a truck has been on delay or which operator is on a piece of equipment.

Pitram Connect saves time, reduces radio traffic and the likelihood of misinterpretation, allowing the mine controller to focus on maintaining data integrity without interruption.

Designed to ensure connections can be made to Pitram over the mines wireless network or via a mobile carrier. This flexibility allows users to access mine information whilst offsite, waiting at the airport for a handover or for the dedicated personnel. Pitram Connect provides piece of mind and allows you the visibility that your mine is on track, whilst you are away from site.

MICROMINE does not believe in locking or obfuscating data collected. As a result Pitram Specialists have developed Pitram Restful Integration Services (PRIS) to allow third party software applications to submit and retrieve Pitram data without needing direct access to the database. Based on current, industry standard integration technology, PRIS enables any organisation to more easily incorporate Pitram data into their Enterprise information systems.

PRIS utilises the “Restful Service” web service technology and provides a means for any third party application, including mine design packages, enterprise resource planning (ERP) systems, and corporate reporting systems, to extract data from Pitram. Through the use of this technology, systems are able to extract data from Pitram without the need for in-depth knowledge of how Pitram data is stored and without risking the integrity of the Pitram data.

As an example, directly querying any systems database to extract information, on occasions the data extraction method may cause knock on problems throughout these systems. Slow responding systems when poorly designed/written queries are executed (VBA scripts from Excel) is a potential problem with most mining packages, PRIS is designed to eliminate these types of occurrences.

PRIS is based on REST, any client application, on any platform, written in any programming language, may interact with services using simple URLs on top of HTTP. PRIS can also be used to submit data to Pitram in a safe and structured manner. Third party systems such as autonomous loading and hauling systems, conveyor systems or weighbridges can submit data to Pitram. This data is treated in the same manner as data recorded through the Pitram control room and is available for reporting immediately.

Pitram Restful Integration Service (PRIS) handles all traffic to and from Pitram. The PRIS module enables data to be obtained via the mobile interface, so the need to bundle these modules will be required. PRIS utilises the latest API technology to ensure data is always retrieved regardless of internal Pitram data structures.

Pitram Connect provides insight into your mine site at your fingertips. The mobile application will allow users to retrieve information about their assets (people, equipment, production, locations, time allocations) without directly impacting mine control personnel or having to be at a workstation. For example, a production supervisor would like to know the mines current production delivery to the production plant, quickly determine the status of a location, know the amount of time a truck has been on delay or which operator is on a piece of equipment.

Pitram Connect saves time, reduces radio traffic and the likelihood of misinterpretation, allowing the mine controller to focus on maintaining data integrity without interruption.

Designed to ensure connections can be made to Pitram over the mines wireless network or via a mobile carrier. This flexibility allows users to access mine information whilst offsite, waiting at the airport for a handover or for the dedicated personnel. Pitram Connect provides piece of mind and allows you the visibility that your mine is on track, whilst you are away from site.

MICROMINE does not believe in locking or obfuscating data collected. As a result Pitram Specialists have developed Pitram Restful Integration Services (PRIS) to allow third party software applications to submit and retrieve Pitram data without needing direct access to the database. Based on current, industry standard integration technology, PRIS enables any organisation to more easily incorporate Pitram data into their Enterprise information systems.

PRIS utilises the “Restful Service” web service technology and provides a means for any third party application, including mine design packages, enterprise resource planning (ERP) systems, and corporate reporting systems, to extract data from Pitram. Through the use of this technology, systems are able to extract data from Pitram without the need for in-depth knowledge of how Pitram data is stored and without risking the integrity of the Pitram data.

As an example, directly querying any systems database to extract information, on occasions the data extraction method may cause knock on problems throughout these systems. Slow responding systems when poorly designed/written queries are executed (VBA scripts from Excel) is a potential problem with most mining packages, PRIS is designed to eliminate these types of occurrences.

PRIS is based on REST, any client application, on any platform, written in any programming language, may interact with services using simple URLs on top of HTTP. PRIS can also be used to submit data to Pitram in a safe and structured manner. Third party systems such as autonomous loading and hauling systems, conveyor systems or weighbridges can submit data to Pitram. This data is treated in the same manner as data recorded through the Pitram control room and is available for reporting immediately.

Pitram Restful Integration Service (PRIS) handles all traffic to and from Pitram. The PRIS module enables data to be obtained via the mobile interface, so the need to bundle these modules will be required. PRIS utilises the latest API technology to ensure data is always retrieved regardless of internal Pitram data structures.