About Centrifugal Pump Spec

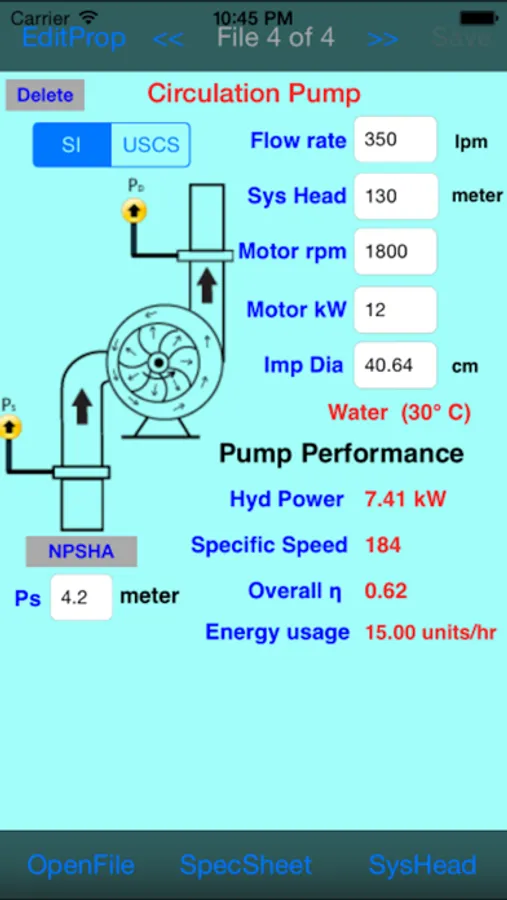

CPspec guides to determine the three key factors of a centrifugal pump design specification such as ‘System Head’, ‘NPSHA’ and ‘Sizing’ in order to unveil the potential for energy savings. A judicious selection of pump is very essential for its energy efficiency and long-term satisfactory performance. Users can create as many spec sheets for given application and save it in a file for further evaluation. Choosing a right spec is often an iterative process and this app can become very handy for all design and practicing engineers to accomplish this goal.

By default, pump manufacturers provide performance curve for water that is valid for other liquids too. However, there could be significant impact on performance due to increase or decrease in system head as well as NPSHA while using other liquids or oils at elevated temperatures. One can quickly compute these values for liquids other than water using the model provided in this app. There are four main sections in this app and its features are briefly given below with respective screen shots.

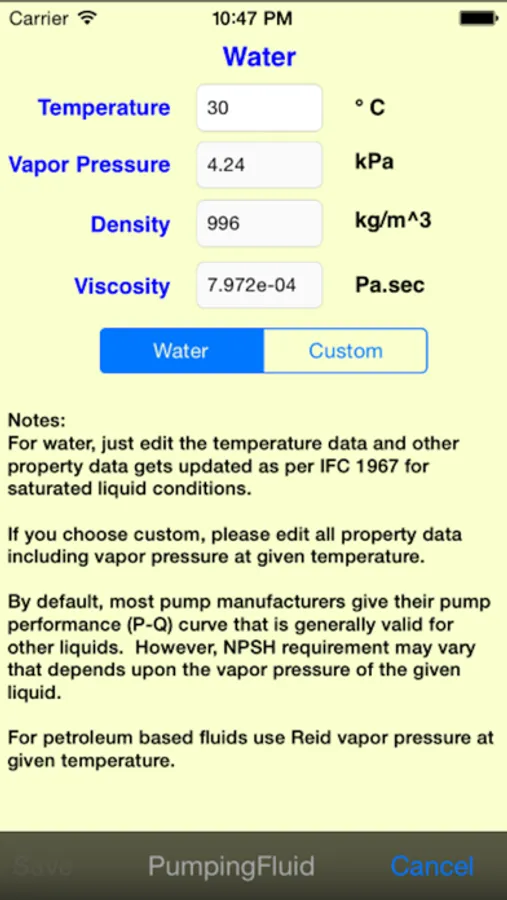

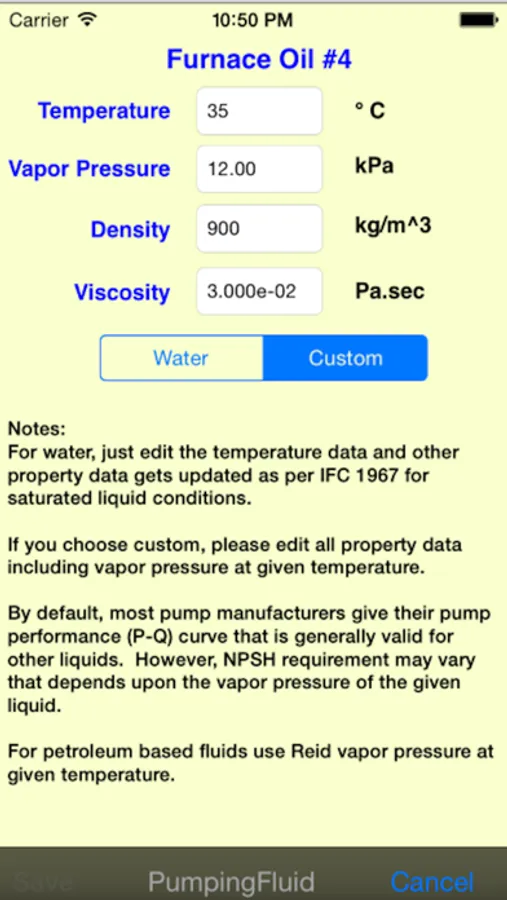

Fluid Properties:

Water used as a standard liquid medium and its transport properties are determined based on IFC 1967 for the given temperature. For liquids other than water, users can create custom liquid with specific name and its properties for computation of system head and NPSH. Users can choose any unit standard (SI or USCS) to input the data. in the screen shot, furnace oil is used as a custom fluid.

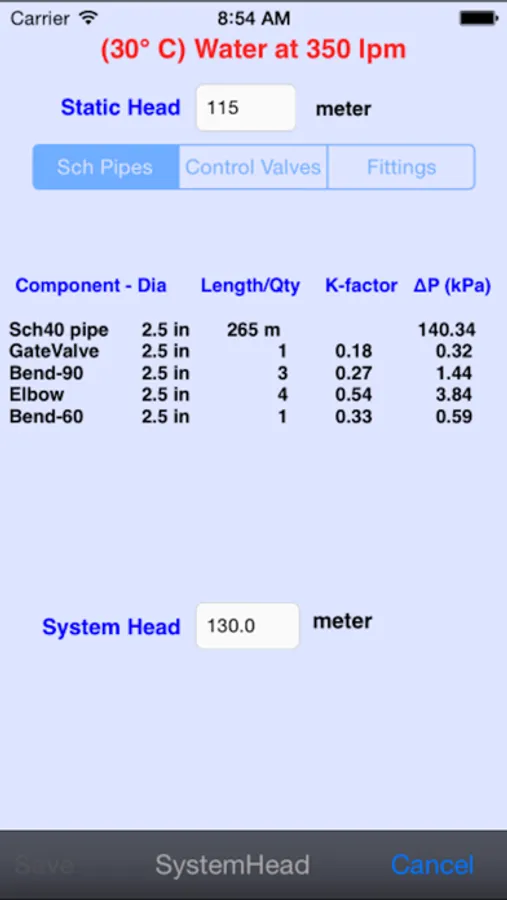

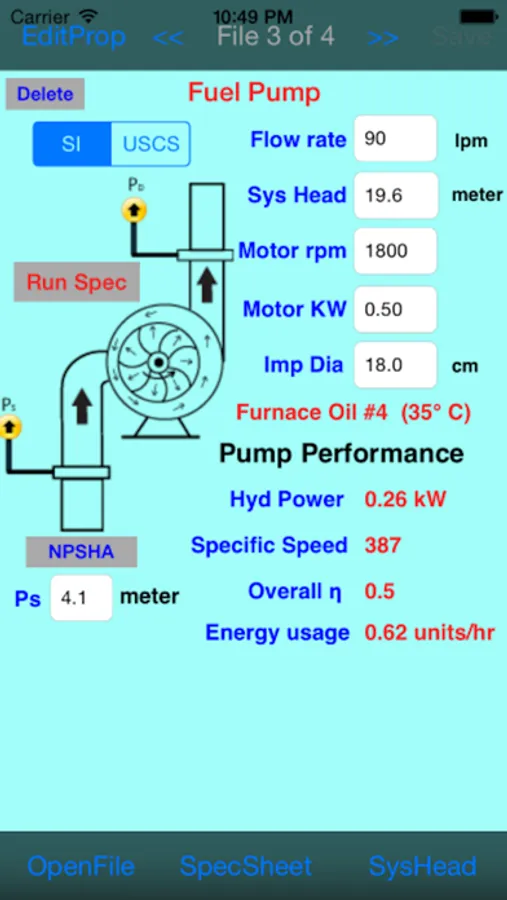

System Head:

One can quickly build a pump circuit comprises of different schedule pipes, valves and fittings with total quantity. Based on property data, the app computes the total pressure drop for the given circuit. The total system head is then computed based on the static head data (pump center line to final delivery including discharge pressure if any) and final values are then posted to the spec sheet with possible starting impeller and motor sizes for iteration. This can be further edited as per suppliers/manufacturers data.

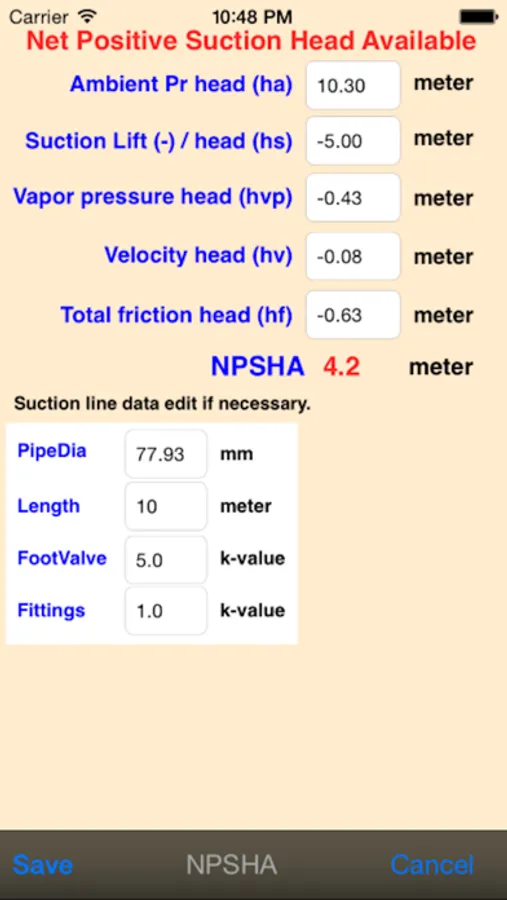

NPSHA (Net Positive Suction Head Available):

This is an important design parameter in order to avoid any cavitation in the pump. Every pump manufacturer provides their data on NPSH requirement. Therefore, it is very essential to compute this value to ensure that pump meets this requirement. Based on the property and size data, this is computed for a default suction line that can be edited for accuracy.

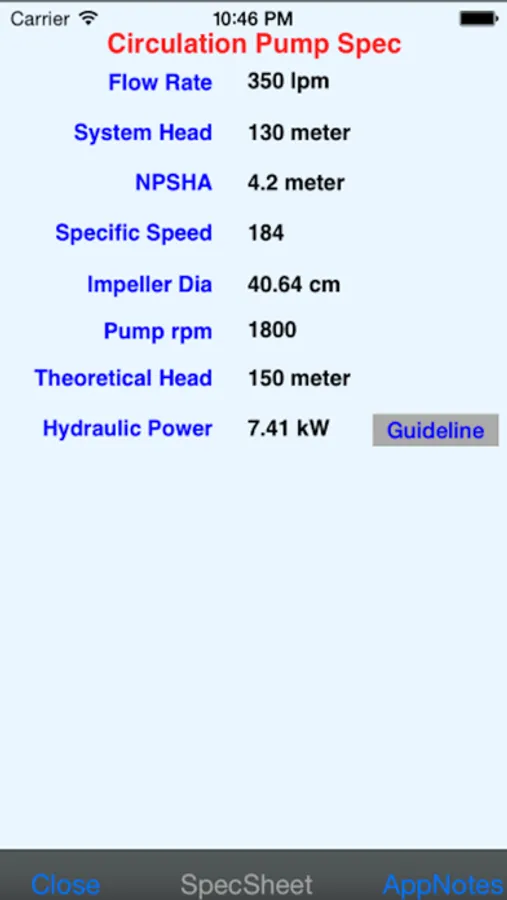

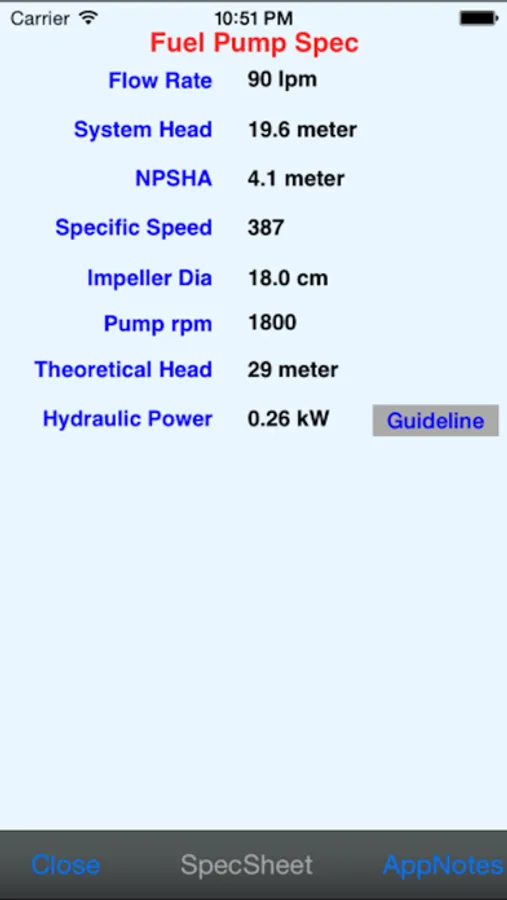

Pump spec summary:

Summary sheet provides all the major key pump design parameters with general guidelines to help the users to choose the right pump for their application. This is to further insure energy efficiency and long-term performance of the pump.

In this version app notes has a link to a complete documentation on implementation and validation of math-model used in respective apps along with guidelines to plan different periodic maintenance activities based on equipment performance indices.

By default, pump manufacturers provide performance curve for water that is valid for other liquids too. However, there could be significant impact on performance due to increase or decrease in system head as well as NPSHA while using other liquids or oils at elevated temperatures. One can quickly compute these values for liquids other than water using the model provided in this app. There are four main sections in this app and its features are briefly given below with respective screen shots.

Fluid Properties:

Water used as a standard liquid medium and its transport properties are determined based on IFC 1967 for the given temperature. For liquids other than water, users can create custom liquid with specific name and its properties for computation of system head and NPSH. Users can choose any unit standard (SI or USCS) to input the data. in the screen shot, furnace oil is used as a custom fluid.

System Head:

One can quickly build a pump circuit comprises of different schedule pipes, valves and fittings with total quantity. Based on property data, the app computes the total pressure drop for the given circuit. The total system head is then computed based on the static head data (pump center line to final delivery including discharge pressure if any) and final values are then posted to the spec sheet with possible starting impeller and motor sizes for iteration. This can be further edited as per suppliers/manufacturers data.

NPSHA (Net Positive Suction Head Available):

This is an important design parameter in order to avoid any cavitation in the pump. Every pump manufacturer provides their data on NPSH requirement. Therefore, it is very essential to compute this value to ensure that pump meets this requirement. Based on the property and size data, this is computed for a default suction line that can be edited for accuracy.

Pump spec summary:

Summary sheet provides all the major key pump design parameters with general guidelines to help the users to choose the right pump for their application. This is to further insure energy efficiency and long-term performance of the pump.

In this version app notes has a link to a complete documentation on implementation and validation of math-model used in respective apps along with guidelines to plan different periodic maintenance activities based on equipment performance indices.