About Boiler Efficiency

BoilerFE can run a quick preliminary audit on boiler efficiency and various losses associated in generation of pressurized steam. Users can create their specific boiler application including CHP (Brayton) cycle and save it in a file for time to time performance review. Thus it would also enable users to compare different grade of fuels used in the same boiler under similar conditions. Therefore, this app can be very helpful to energy engineers and auditors in assessing the potential savings as well as to identify areas for improvement.

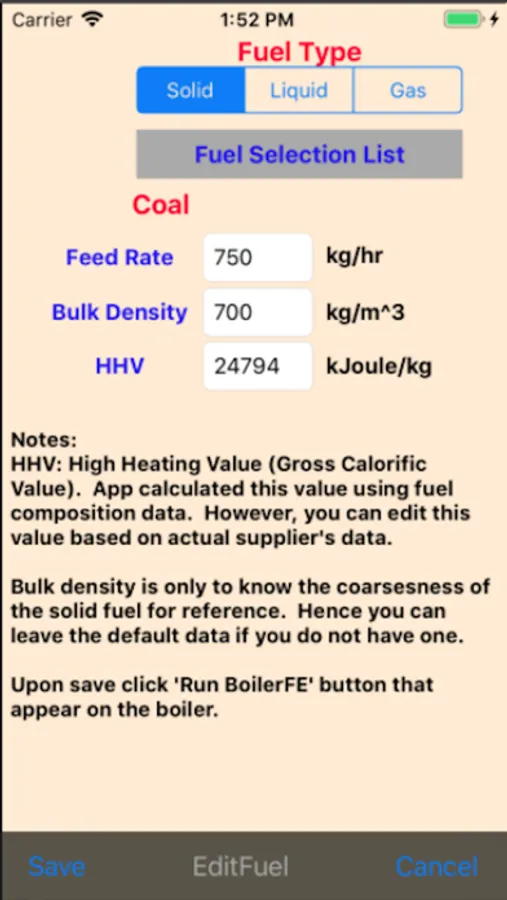

App covers different types of boilers including CHP with option to select fuels such as coal, oil and gases with specific compositions. Following is the list of fuels under each category one can select from the picker. Each fuel has a default calorific value (HHV) based on certain composition. Users can edit this default value for accuracy. For fuels that are not in the list, users can create a custom fuel with composition and calorific value.

Coal:

Coal-Illinois, Coal-Pennsylvania, Coal-Ohio, Coal-W.VA, Coal- Kentucky, Coal, Custom.

Fuel Oil:

Furnace Oil#1, Furnace Oil#2, Furnace Oil#3, Furnace Oil#4, Furnace Oil#5, Furnace Oil#6, LSHS, Methanol, Ethanol, LPG, Kerosene, HSD, Custom.

Gas:

Methane, Ethane, Propane, Butane, Natural gas, Custom.

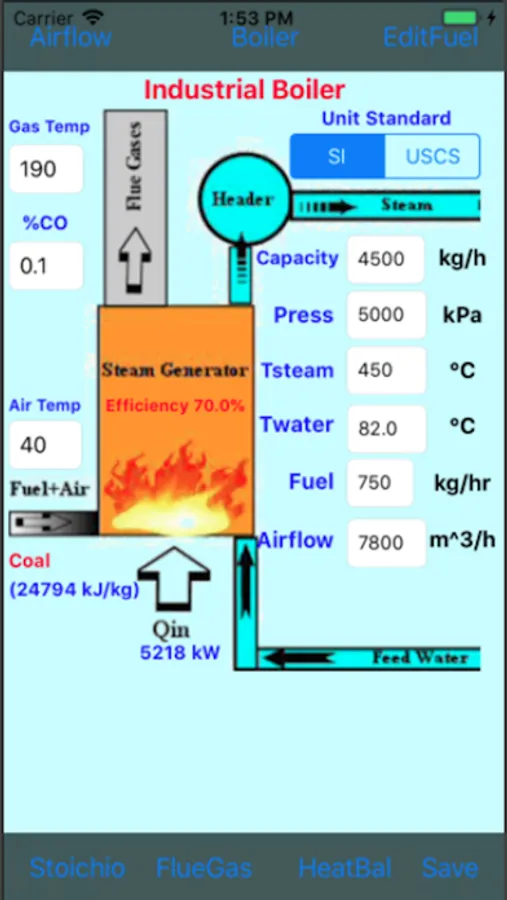

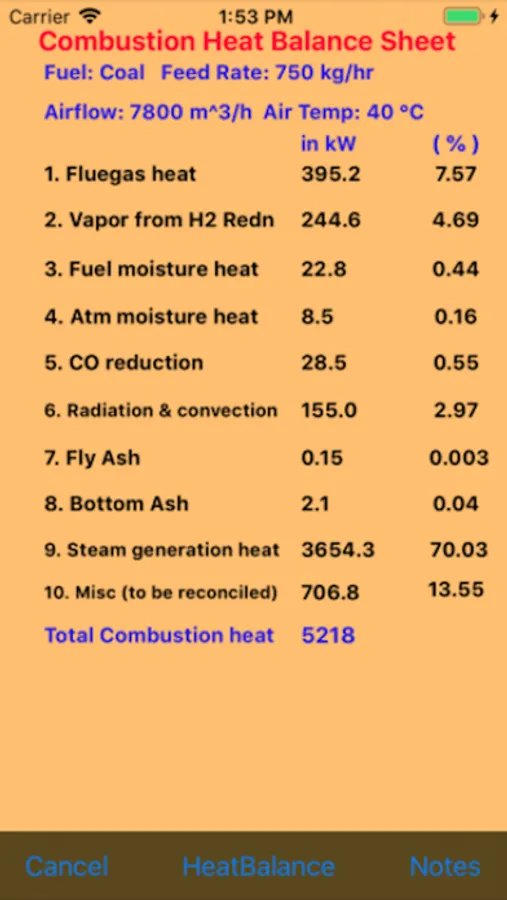

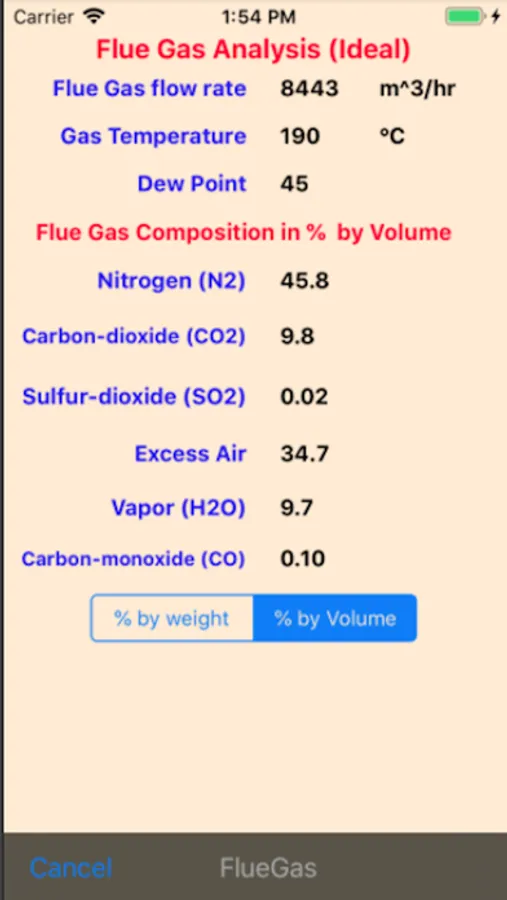

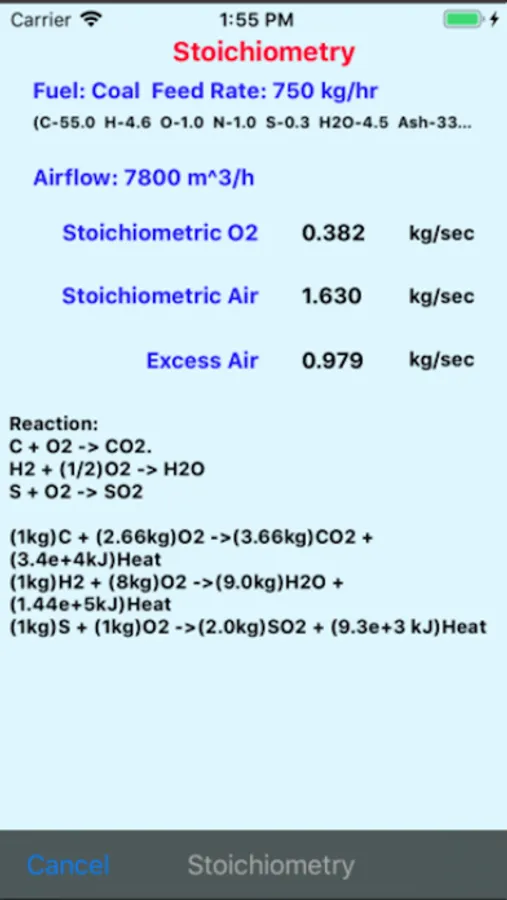

By default, App uses a generic Coal fired in an industrial boiler that can be edited for more specific applications. The screen shots displays this example with results on heat balance sheet, flue gas analysis and stoichiometry. A brief description of the combustion model used in this app is also provided in App notes for reference.

Type of boilers and inputs:

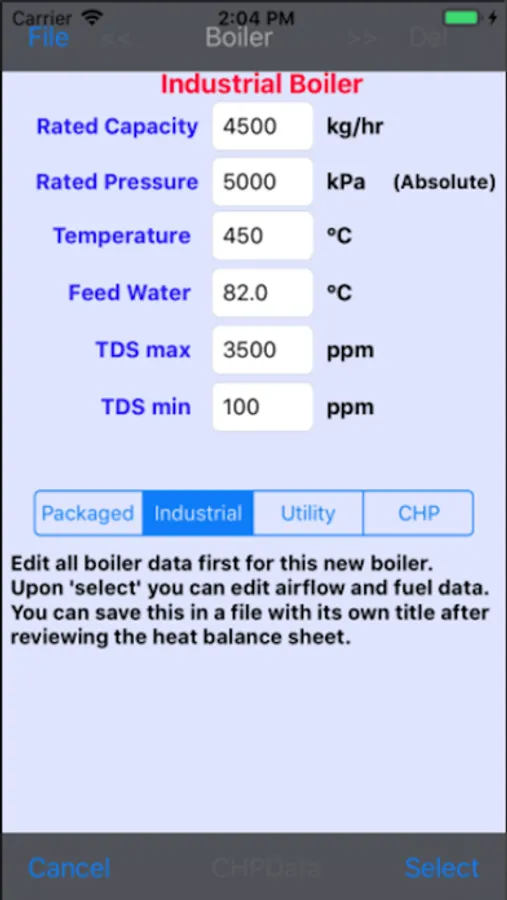

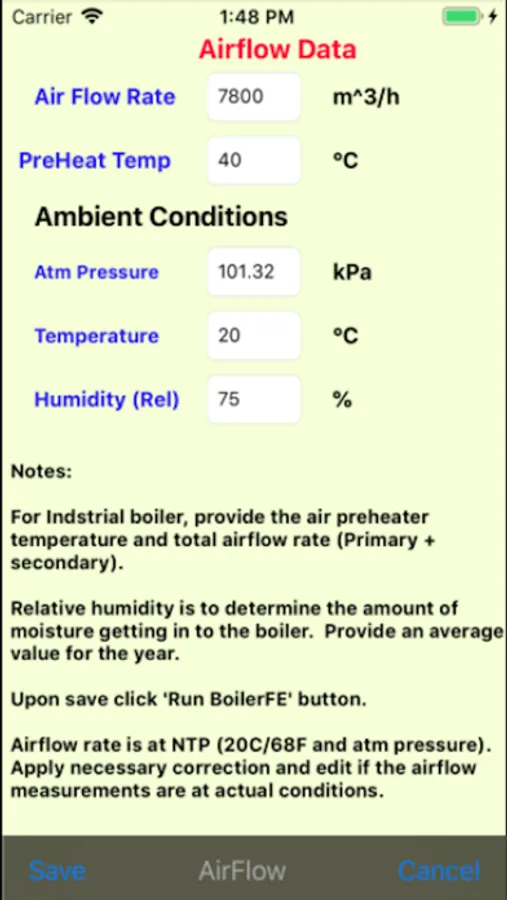

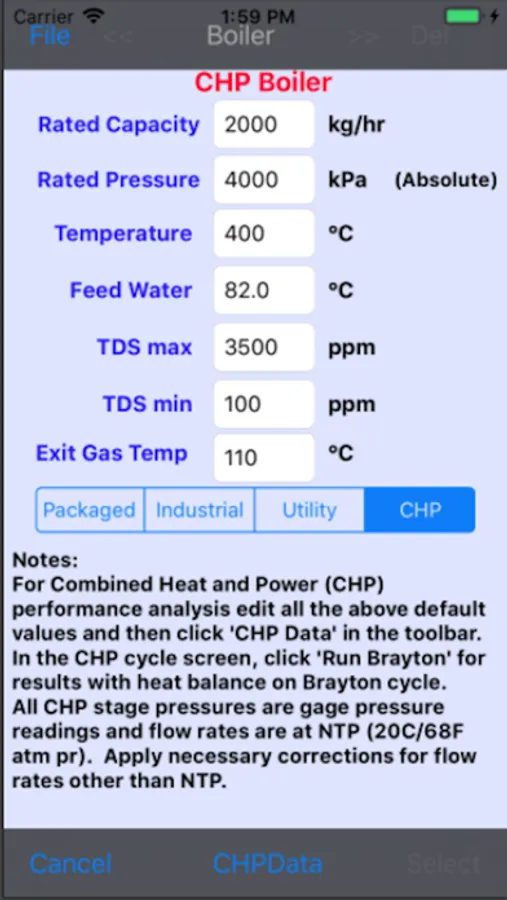

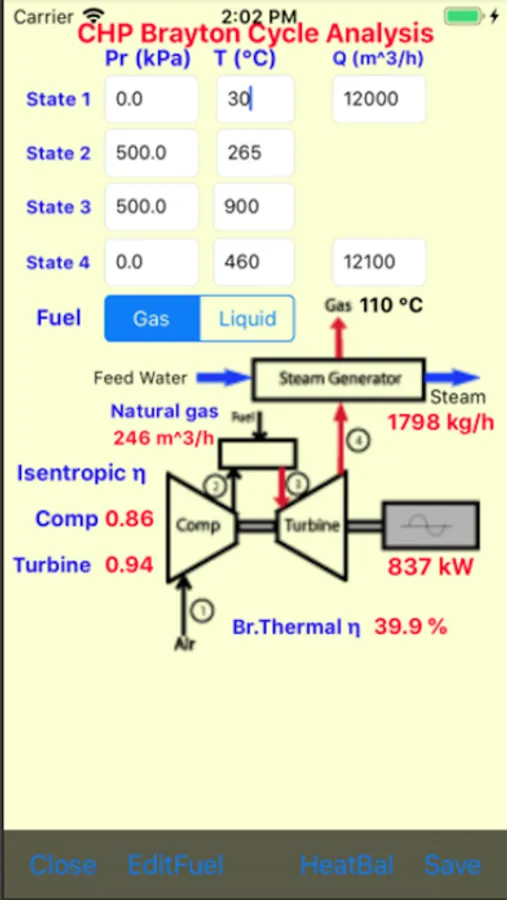

App covers packaged, industrial and utility boilers with specific design data for efficiency and heat balance calculations. Users can conveniently choose the different unit standards for data input. Input such as airflow, fuel type and feed rate can be edited for more specific application using the respective editable tool bar buttons. There is a separate section on CHP (Brayton) cycle that is activated from Boiler info screen. All CHP data can be saved as well with unique titles and reloaded as and when required. Foot notes are provided to help edit different input parameters.

Result:

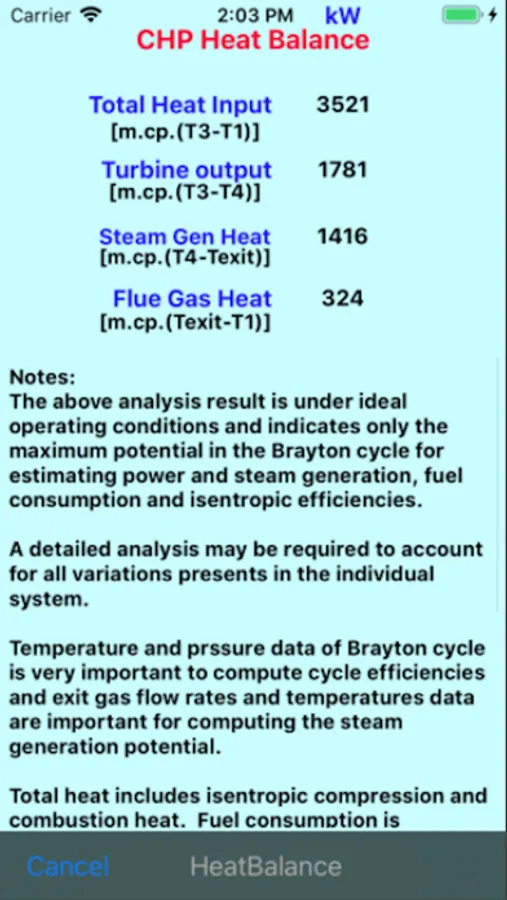

Besides computation of boiler efficiency using direct method, app provides the following results as shown in the screen shots.

1.Heat balance sheet

2.Flue gas analysis

3.Stoichiometric analysis of the combustion process.

In this version, the app notes has the link for a complete documentation of implementation and validation of math-model used in individual apps. Also in addition this document includes guidelines to plan periodic maintenance activities required for a satisfactory performance of different energy intensive equipment such as boiler, pump, heat exchangers etc. commonly used in process industries.

App covers different types of boilers including CHP with option to select fuels such as coal, oil and gases with specific compositions. Following is the list of fuels under each category one can select from the picker. Each fuel has a default calorific value (HHV) based on certain composition. Users can edit this default value for accuracy. For fuels that are not in the list, users can create a custom fuel with composition and calorific value.

Coal:

Coal-Illinois, Coal-Pennsylvania, Coal-Ohio, Coal-W.VA, Coal- Kentucky, Coal, Custom.

Fuel Oil:

Furnace Oil#1, Furnace Oil#2, Furnace Oil#3, Furnace Oil#4, Furnace Oil#5, Furnace Oil#6, LSHS, Methanol, Ethanol, LPG, Kerosene, HSD, Custom.

Gas:

Methane, Ethane, Propane, Butane, Natural gas, Custom.

By default, App uses a generic Coal fired in an industrial boiler that can be edited for more specific applications. The screen shots displays this example with results on heat balance sheet, flue gas analysis and stoichiometry. A brief description of the combustion model used in this app is also provided in App notes for reference.

Type of boilers and inputs:

App covers packaged, industrial and utility boilers with specific design data for efficiency and heat balance calculations. Users can conveniently choose the different unit standards for data input. Input such as airflow, fuel type and feed rate can be edited for more specific application using the respective editable tool bar buttons. There is a separate section on CHP (Brayton) cycle that is activated from Boiler info screen. All CHP data can be saved as well with unique titles and reloaded as and when required. Foot notes are provided to help edit different input parameters.

Result:

Besides computation of boiler efficiency using direct method, app provides the following results as shown in the screen shots.

1.Heat balance sheet

2.Flue gas analysis

3.Stoichiometric analysis of the combustion process.

In this version, the app notes has the link for a complete documentation of implementation and validation of math-model used in individual apps. Also in addition this document includes guidelines to plan periodic maintenance activities required for a satisfactory performance of different energy intensive equipment such as boiler, pump, heat exchangers etc. commonly used in process industries.